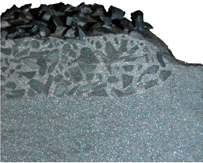

ATC Overlay

ATC GROUP has always been driven to be the absolute leader in the field of hardfacing and tungsten carbide overlay.

To achieve this we constantly evolve our process, experimenting with application technology, matrix selection, alloys and pre/post heat treatment regimes.

We have even developed our own tungsten grit composites – combining various alloys that allow our product to reduce wear whilst withstanding high heat and corrosion.

Tungsten carbide overlay – had a bad experience? Click here…

Why does ATC OVERLAY perform better?

- We only use the highest grades of tungsten carbide grit.

- We use a variety of matrix steels to ensure the best performance in all conditions.

- When the situation demands, we blend tungsten and various alloy grits resulting in composites that can withstand and perform at temperatures in excess of 1200 degrees Celsius. One of our most popular custom blends is highly resistant to high temperature corrosion (oxidization).

- Tungsten is deposited evenly through the weld pool achieving parent metal penetration up to 3.0mm

- Pressurised tungsten delivery through shielding gas results in high level tungsten saturation (65%) with no craze cracking or porosity.

- We have a very limited heat affected zone.

- We can successfully overlay high Chrome alloys including whiteirons and Nihard.

- We have developed an “impact resistant overlay” that will far exceed standard tungsten overlay life expectancy.

- We have developed a superhard tungsten overlay successfully impregnating HRC 90 TUNGSTEN + HARDENING ALLOY GRIT + HRC 60 matrix wire + Heat Treatment resulting in HRC 71 MATRIX.

This composite overlay is proving very successful in high abrasion – very low impact environments. - Computerised grit delivery system results in even consistent overlay finish.

- We are very experienced at what we do. We have developed patterns and techniques solely designed to reduce the amount of overlay we put on your components, whilst still achieving the best results possible. The less we put on – the less we charge. We feel it is our duty save you money wherever we can.

- We are honest and upfront. If we can’t achieve what you want – we will tell you! If there is a hardfacing process or ceramic better suited to your needs – we will tell you!